I was recently contacted by a client about the repair of a Panerai 113. I agreed to do the work and thought I would share the repair process here.

Here is the watch…

The customer said that the watch would not wind, so the first thing that came to mind was that the set lever screw had come loose, which is common and simple to fix. However when I received the watch and tried some things it was clearly a different problem – the watch would wind but generated no power. I had a good idea what was wrong.

After removing the strap, I open the case back:

In order to remove the movement, the stem has to come out, so the crown lock has to come off:

Here is the movement out of the case:

Next the hands come off, and I use a protective shield to make sure the hand levers do not damage the dial:

The hands are removed:

Next the dial is removed – nice perlage on the bottom plate:

Here I have removed the winding/setting mechanism:

Next I went straight to the barrel bridge, removing it to get the barrel out as this is where I think the problem really is:

When I opened the barrel, there is the problem – broken mainspring. I’ve added some arrows where you can see the two ends of the broken spring:

Here is the spring out of the barrel, and you can see the inner coil that attaches to the arbor is broken:

Since the watch has been used for 4 years every day, time for a full service anyway, so I’m carrying on with the disassembly:

Now everything’s apart and segregated by function in the storage trays:

So I will order a new mainspring for the watch, but while I wait for that I might as well continue with the cleaning. Here the parts are placed in mesh baskets for the ultrasonic cleaner:

The two baskets go through 4 different jars of solutions – here the parts are in the second jar:

Here is a shot of a jar with the parts in my ultrasonic machine:

So I’ve finished cleaning everything now, and the wait for the new mainspring begins.

For an ETA 6497-2 you purchase an entire barrel complete which is the spring already installed in a new barrel – here it is:

I begin by removing the new barrel from the packaging and inspecting it:

It looks fine but before I install it I want to check the barrel arbor end shake to make sure its okay – I hold the barrel steady and use my brass tweezers to move the arbor up and down to check the end shake – its good:

I always like to start reassembly by checking the centering and flatness of the hairspring, and in order to do this the balance jewels need to be lubricated and installed – I start with the bottom plate jewel and add some Mobius 9010 to the cap jewel:

Then I install it on the main plate – here it’s in place and the shock spring just needs to be closed:

I Install the balance in the watch and then lubricate/install the balance jewels on this side, then I can look at the centering of the hairspring – it’s pretty good but did require a small tweak:

Once the spring is centered looking from above, I look to see if it’s centered between the regulating pins – after another small adjustment it looks good:

Now the last step is to close the regulating pins – not tight enough that they pinch the spring just a small clearance on each side:

Then I remove the balance assembly and set it aside. Next I install the train wheels so I can check their end shakes – they were all good so no need to move any jewels:

So now I can carry on with the assembly – here the barrel is installed and the barrel bridge is in place:

Next step is lubricating all the train wheels – in total 7 different lubricants are used in this watch:

Then I install the pallet fork and pallet bridge:

The next step is lubricating the escapement. This is a critical step and can be tricky on smaller calibers especially – on larger movements like this one it’s not so bad. The photo below shows the exit pallet stone (red arrow) and this is where I apply the Mobius 9415 – a special oil used just for this one application. It takes several applications of small amounts of oil and then running the escape wheel around to get the proper amount in place:

Next I install the balance again and get the watch running. I put it on the timing machine and make the initial adjustments:

The watch is checked in 5 positions at full wind and 5 positions at full wind minus 24 hours. Once it looks close I proceed to installation of the dial/hands. Here the hour wheel and dial washer are both in place, the dial is ready to be installed:

Now with the dial on I check the hands:

With all the hands installed, I check to make sure all the hands clear each other:

The case is cleaned out and the movement placed in it, then the stem is lubricated:

Next the movement clamps are installed:

Now the case back gasket can be lubricated before installation:

Now the watch is mostly assembled.

I did some timing checks to make sure the watch ran well – I do this by winding the watch and putting it in a specific position (dial up, dial down, crown down, crown left, and crown up) and compare the gain or loss 24 hours later against a known standard….time.gov.

The watch ran fine so I moved on to the final assembly and testing steps. I have to install the crown lock system first…

Now that is installed and we are ready to pressure test the watch.

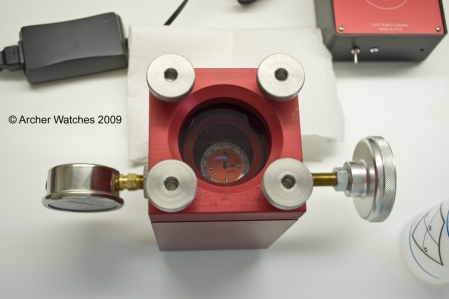

The pressure testing with this type of tester involves suspending the watch in a chamber above the water line, and then raising the pressure inside the chamber. Here the watch is inside and I have raised the pressure to 10 atmospheres.

After a couple of minutes I lower the watch into the water, and slowly release the pressure from the chamber. If the watch case has a leak, the pressure inside the case would have equalized with the pressure in the chamber when the watch was out of the water. Now as I lower the pressure inside the chamber, the pressure is the watch would be higher, and air would escape and show a stream of bubbles.

Some bubbles may appear but as long as they are single bubbles and not a stream coming from a point, there is no leak. No streams of bubbles on this one so it’s good!

Now time to mount the strap.

All done and ready to be shipped out to the customer.

I hope you enjoyed this look at how a repair is done.

Cheers, Al

archer.watches(at)sympatico.ca

http://www.archerwatches.ca/

After that is complete, I place the balance cock and the balance fires right up:

After that is complete, I place the balance cock and the balance fires right up: